Poster Making Machine Sublimation Science

What Makes Poster Making Machine Sublimation Labs So Revolutionary?

Let’s get nerdy for a hot minute (pun intended). Sublimation printing uses heat to transfer dye directly into synthetic materials, creating permanent, vibrant designs that won’t peel, crack, or fade. When you combine this technology with a Fundraiser Pro 1000 Sublimation Printer, you’re not just making custom lab gear—you’re demonstrating real-world applications of phase transitions and molecular bonding. Talk about making chemistry tangible!

But here’s where it gets really exciting. This isn’t your typical “print and stick” situation. Sublimation creates a molecular-level bond between the dye and the material, which means those safety labels and custom designs become part of the fabric itself. Your students can literally see science in action while creating practical solutions for lab organization. Plus, when students help design and create their own safety equipment, they’re way more likely to actually use it. (Trust me, I’ve seen the data on this!)

The Science Behind the Magic: Teaching Heat Transfer Through Sublimation

Sublimation Temperature

The magic number where solid dye transforms directly to gas

Transfer Time

Quick molecular bonding for permanent results

Permanence Rate

Molecular-level bonding means no peeling or fading

Practical Projects That Combine Safety with School Spirit

Ready to see this in action? Let me share some of my favorite projects that have transformed STEM classrooms across the country. These aren’t just crafts—they’re functional safety solutions that students actually want to use.

Creating a Poster Making Machine Sublimation Labs System

Let’s talk implementation. Setting up a sublimation system in your STEM classroom isn’t just about buying equipment—it’s about creating a sustainable program that enhances learning while improving safety. Here’s my tested blueprint for success.

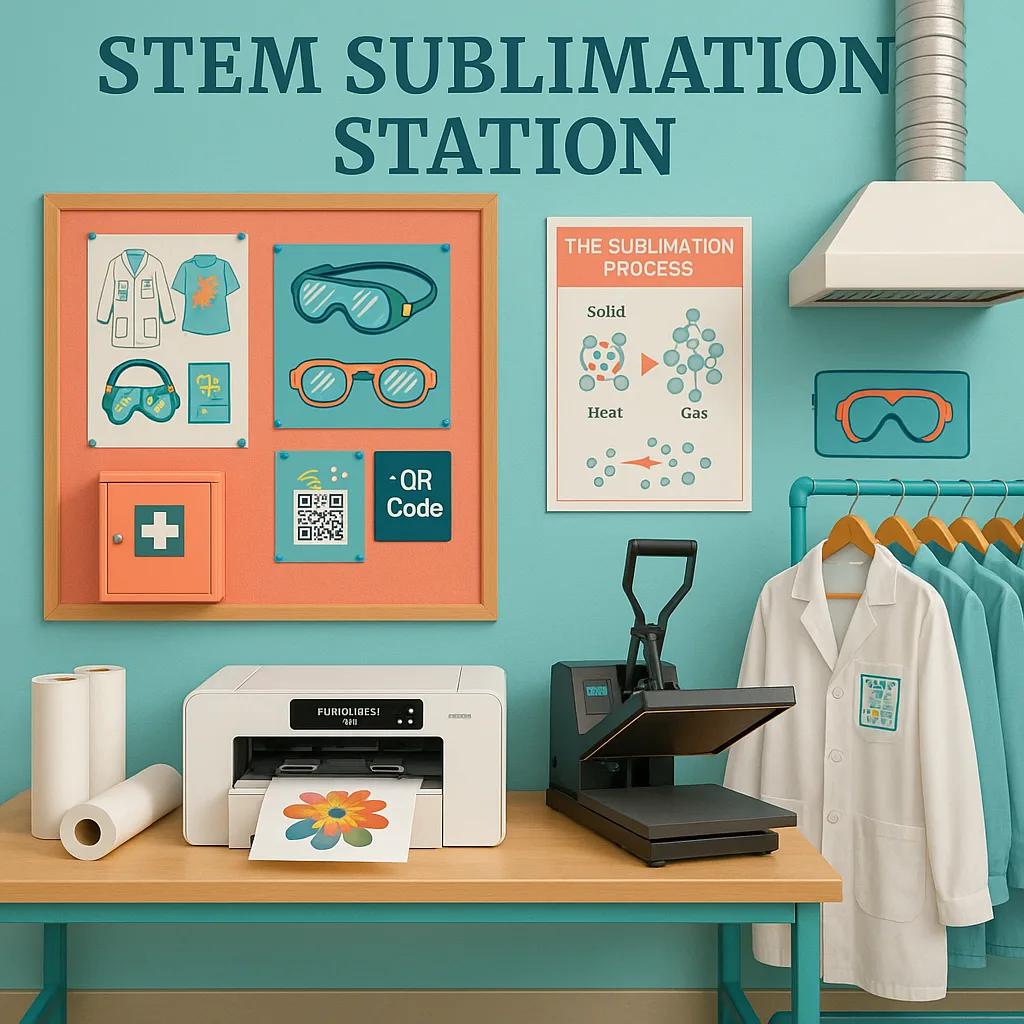

First, designate a specific area for your sublimation station. You’ll need proper ventilation (those fumes need somewhere to go!), a heat-resistant surface, and storage for materials. Consider creating a “Sublimation Science Station” complete with educational posters explaining the process. Speaking of posters, this is where your poster making machine really shines—create large-format visuals showing the molecular process, safety procedures, and design inspiration.

Next, develop a curriculum integration plan. Sublimation projects can enhance units on:

• States of matter and phase transitions

• Chemical bonding and molecular structure

• Heat transfer and thermodynamics

• Material science and polymers

• Design thinking and engineering process

Beyond the Basics: Advanced Sublimation Projects

Once you’ve mastered lab coats and goggle straps, the possibilities explode like a well-conducted chemistry experiment! Here are some next-level projects that combine serious science with serious fun.

Making It Happen: Budget-Friendly Implementation

I know what you’re thinking: “This sounds amazing, but my budget is tighter than a sealed beaker!” Fear not, my budget-conscious colleague. Let me break down how to make this work without breaking the bank.

Start small with a basic sublimation printer. The Fundraiser Pro 1000 is perfect for getting your feet wet without drowning in costs. You can create an entire semester’s worth of custom safety equipment for less than the cost of ordering pre-made items. Plus, here’s a secret: once other departments see what you’re doing, they’ll want in. I’ve seen schools turn their sublimation stations into profit centers by creating custom items for sports teams, clubs, and events.

Consider these cost-saving strategies:

• Partner with the art department for design work

• Use student-created designs (hello, cross-curricular learning!)

• Buy polyester items in bulk during back-to-school sales

• Apply for STEM grants specifically for safety equipment

• Start a “Lab Safety Makeover” fundraiser

Student Engagement: The Secret Sauce

Here’s something they don’t teach in education school: students care infinitely more about safety when they’ve had a hand in creating the safety equipment. It’s like the IKEA effect but for lab gear! When students design their own safety equipment using your poster printer machine, they’re not just following rules—they’re investing in the process.

I’ve seen this transformation happen countless times. That kid who always “forgot” their safety goggles? Once they designed custom straps featuring their favorite video game character (in school colors, of course), those goggles became their prized possession. The student who rolled their eyes at lab coat requirements? After creating a coat with a periodic table design where each element represented a friend in class, they wore it with pride.

This engagement extends beyond individual items. Create class competitions for best safety slogan designs, most creative use of school colors, or most informative QR code integration. Suddenly, safety isn’t something imposed on students—it’s something they own and celebrate.

Your Next Steps: Launching Your Sublimation Lab

Ready to transform your STEM classroom into a sublimation science wonderland? Here’s your action plan:

Week 1-2: Research and Planning

Start by assessing your space and budget. Check out our total cost of ownership guide to understand the long-term investment. Survey your students about what custom safety equipment would make them most excited about lab work.

Week 3-4: Equipment Acquisition

Choose your sublimation printer based on your needs. For most classrooms, the Fundraiser Pro 2400 offers the perfect balance of capability and affordability. Don’t forget to explore funding sources—many grants specifically support innovative STEM safety initiatives.

Week 5-6: Pilot Program Launch

Start with one simple project—custom name tags for lab coats or equipment labels. Document the process, including the science lessons integrated into the activity. Use this documentation to showcase the program’s value to administrators and potential funders.

Week 7-8: Full Implementation

Roll out your complete poster making machine sublimation labs program. Create a schedule that allows each class to design and produce their custom safety equipment while learning about heat transfer, molecular bonding, and material science.