Poster Machine 10-Year TCO Hidden Cost Calculator

Why Traditional Cost Analysis Falls Short

Most schools evaluate poster machines based solely on purchase price and basic supply costs. However, this approach overlooks numerous hidden expenses that accumulate over a decade. Through my work with dozens of schools, I’ve identified critical cost factors that traditional analyses miss entirely.

Consider this: when Sunnyvale Elementary first approached me about purchasing a poster machine, they had budgeted $15,000 based on equipment and supply estimates. By applying our comprehensive TCO framework, we discovered their actual 10-year investment would approach $45,000—triple their initial projection. Understanding these hidden costs transformed their decision-making process and ultimately led to smarter choices.

The reality is that every poster program involves complex financial dynamics. From staff training hours to storage infrastructure, these overlooked elements significantly impact your bottom line. Let’s explore each component to help you make truly informed decisions.

Poster Machine TCO Calculator: The Complete Framework

Building an accurate financial model requires examining both obvious and hidden costs. Here’s the comprehensive framework I use when consulting with schools:

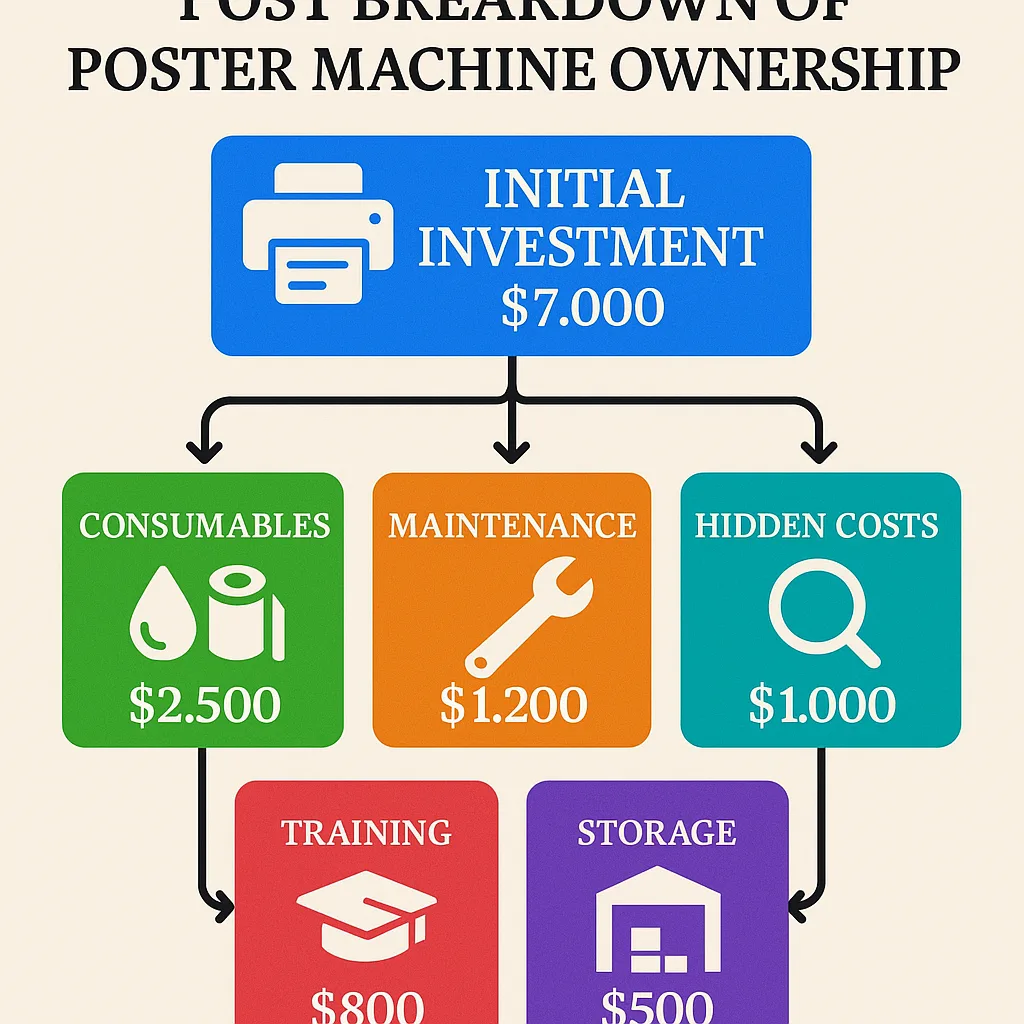

Initial Investment Components

The upfront costs extend far beyond the printer itself. When evaluating the best poster printer for schools, consider these essential investments:

Equipment costs vary significantly based on your chosen model. The Campus Pro 36 Poster Maker Advanced Package provides exceptional value with its comprehensive starter kit, while the Classroom Pro 24 Poster Maker Elite Package offers a more compact solution for smaller schools.

Annual Operating Expenses

Operating costs accumulate steadily over time. Based on data from our comprehensive printing cost analysis, here’s what schools typically spend annually:

Quick Reference Guide

Note: Costs assume 5% annual inflation and moderate usage (100-150 posters/month)

The Hidden Costs Nobody Talks About

Storage Infrastructure

Many schools underestimate storage needs for paper rolls, ink cartridges, and finished posters.Real Storage Costs

Annual storage costs average $800-$1,200 when factoring in:• Climate-controlled space for media

• Organized shelving systems

• Inventory management time

• Damaged materials from poor storage

Staff Time Investment

Training, troubleshooting, and project management consume significant staff hours.Time = Money

Based on average teacher salaries:• Initial training: 20 hours = $800

• Weekly management: 2 hours = $3,200/year

• Project assistance: 40 hours/year = $1,600

• Total annual time cost: $5,600

Opportunity Costs

What else could that money accomplish for your students?Lost Revenue Potential

$50,000 over 10 years could fund:• 25 classroom technology upgrades

• 100 field trips

• 500 new library books

• Professional development for 15 teachers

Consider these alternatives carefully.

Quality Control Failures

Misprints, color corrections, and learning curves create substantial waste.Waste Adds Up

Average waste percentages:• Year 1: 15-20% of materials

• Years 2-3: 8-10%

• Years 4+: 5-7%

This translates to $300-$600 annually in wasted supplies, plus staff time.

Making the Numbers Work for Your School

After analyzing hundreds of school poster programs, I’ve identified key strategies that significantly reduce total costs while maximizing educational impact. The best poster printer for schools isn’t necessarily the most expensive—it’s the one that aligns with your usage patterns and budget constraints.

Volume Thresholds for ROI

Based on comprehensive data from our comparison with Canon and Epson models, schools printing fewer than 50 posters monthly rarely achieve positive ROI on poster machine investments. However, schools producing 100+ posters monthly typically save $8,000-$12,000 annually compared to outsourcing.

The sweet spot for most K-12 institutions falls between 75-150 monthly posters. At this volume, in-house printing delivers:

Poster Machine TCO Calculator: Smart Strategies

Transform your poster program from cost center to educational asset with these proven approaches:

Shared Resources

Partner with neighboring schools to split costs and maximize usage. Three schools sharing one machine reduce individual costs by 60%.

Revenue Generation

Offer printing services to PTOs, local businesses, and community groups. Many schools generate $500-$1,500 monthly.

Student Integration

Create design clubs and integrate poster-making into art, marketing, and technology curricula for educational value.

Your Action Plan: From Analysis to Implementation

Understanding true costs empowers better decisions. Whether you choose in-house printing or outsourcing, the key lies in matching your solution to your school’s unique needs. Start by documenting your current poster usage, then apply our TCO framework to project realistic 10-year costs.

Remember, the most expensive mistake is choosing without complete information. By accounting for all costs—visible and hidden—you’ll select a poster solution that enhances education while respecting budget constraints. Our students deserve vibrant, engaging learning environments, and smart financial planning makes that possible.

For personalized guidance on selecting the right poster machine for your school, explore our comprehensive comparison guide or consult our funding sources directory to offset initial investments.

Dr. Emily Carter has helped over 200 schools optimize their poster programs through data-driven decision making. Connect with her at educational conferences nationwide or through schoolpostermakers.com’s professional development resources.